-

Tyler MartinThe quality of the PCBs I received from this company was outstanding. They were well-made and exceeded my expectations.

Tyler MartinThe quality of the PCBs I received from this company was outstanding. They were well-made and exceeded my expectations. -

Olivia AndersonI've been using this company for all of our company PCB needs for years and I have never been disappointed. Their products are always consistent and reliable, and their prices are very competitive.

Olivia AndersonI've been using this company for all of our company PCB needs for years and I have never been disappointed. Their products are always consistent and reliable, and their prices are very competitive. -

Ashley Williamswell-packaged and arrived in perfect condition. I would definitely recommend them to anyone in need of high-quality PCBs

Ashley Williamswell-packaged and arrived in perfect condition. I would definitely recommend them to anyone in need of high-quality PCBs

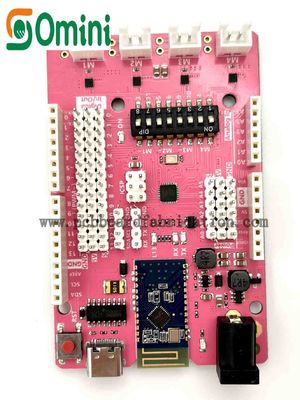

Pink Capacitor Metal Core PCB Manufacturer New Energy Automotive PCBA

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Base Material | FR-4, Components | Component Brand | TI, ST |

|---|---|---|---|

| Copper Thickness | 2 OZ | Layer | 6 Layer |

| Surface Finishing | Immersion Gold | Board Thickness | 1.6 Mm |

| Application | New Energy, Industrial, Consumer Appliances, Automotive | Product Name | Automotive PCBA Assembly OEM Metal Core PCB Pink Capacitor For New Energy |

| High Light | Pink Capacitor Metal Core PCB Manufacturer,Pink Capacitor New Energy Automotive PCBA,Pink Capacitor Automotive Metal Core PCBA |

||

Automotive PCBA Assembly OEM Metal Core PCB Pink Capacitor for New Energy

Description of PCBA Assembly Printed Circuit Board

SMT stands for Surface Mount Technology, and THT stands for Through-Hole Technology. These are two different methods of mounting electronic components onto a printed circuit board (PCB) during the Printed Circuit Board Assembly (PCBA) process.

In SMT, electronic components are mounted on the surface of the PCB using solder paste and a pick-and-place machine. The components are generally small, such as resistors, capacitors, and integrated circuits. SMT components have leads that are soldered onto the surface of the PCB, rather than through holes in the board.

In THT, electronic components are mounted onto the PCB by inserting leads through holes in the board and soldering them to the other side. THT components are typically larger and have longer leads than SMT components. Examples of THT components include connectors, switches, and large capacitors.

Both SMT and THT methods have advantages and disadvantages. SMT allows for higher component density, smaller PCB size, and automated assembly, resulting in faster and more cost-effective production. However, it can be more challenging to repair or rework SMT components. THT components, on the other hand, are generally more robust and easier to repair or replace, but they require more space on the PCB and may limit the board's routing options. The choice between SMT and THT depends on the specific requirements of the PCB design and the intended application of the electronic device.

Specification of Omini PCBA Assembly Printed Circuit Board

| PCBA solder type | SMT , THT |

| Solder paste/Solder wire/Solder Bar | Lead and lead free(RoHS) |

| Stencil | Laser stencil to ensure spcae IC and BGA components SMT to meet IPC-2 class or above |

| Components size 1 | Passive components: min 01005(0.4mm*0.2mm), 0201 |

| Components size 2 | High Precision IC: min 0.25mm spacing |

| Components packing | Reel, cutting belt, pipe and tray. Post welded components are accepted in bulk |

| Big part mounting accuracy | 0.0375mm |

| PCB types | FR4, metal core, FPC, rigid-flex board |

| PCB size | Minium Board size:50mm*50mm |

| PCB thickness | 0.3mm-4.5mm |

| Components package | Cut Tape, Tube, Reels, Loose Parts |

| File format | BOM List, CAM, PCB, PCBDOC, Pick&Place file, Assembly drawing |

| Componnets details 1 | Passive Down to 01005 size |

| Components details 2 | BGA and QFN For Chip |

| Components details 3 | Doubled-sided SMT Assembly |

| Components details 4 | Fine Pitch to 0.8mils |

| Components details 5 | Part Removal and Replacement |

| Repair and rework | repair bad BGA such as dislocation, deviation, false soldering, etc. |

![]()

![]()

![]()

![]()

![]()

![]()

FAQ:

Q1:Does Omini have enough capacity to prodece high-quality products?

A: Omini has 20 years of history in manufacturing PCB, more than 200 employees and 10,000㎡ factory area.We got the UL, ISO9001 certificates, and our production is sold abroad. We have engouh machines & equipment to ensure the quality, please check our Production Equipment list picturers.

Q2:How long does customers need to wait for the quotation and lead time?

A: We have a prefessional group to deal with your inquiry. In our working time, we will reply to your email within 30 minutes to show we have received your inquiry, Then we will send you our quotation in no more than 6 hours. Please noticed our working time is Monday to Friday, 8am to 24pm.

Q3:How can I make sure my PCB gerber is safety?

A: We promise we won't divulge your gerber to the 3rd party, one of our responsibilities is protecting customer information privacy and security, customer information can be included: company name, address, number, trademark, ect. And we could sign NDA with client if necessary.