-

Tyler MartinThe quality of the PCBs I received from this company was outstanding. They were well-made and exceeded my expectations.

Tyler MartinThe quality of the PCBs I received from this company was outstanding. They were well-made and exceeded my expectations. -

Olivia AndersonI've been using this company for all of our company PCB needs for years and I have never been disappointed. Their products are always consistent and reliable, and their prices are very competitive.

Olivia AndersonI've been using this company for all of our company PCB needs for years and I have never been disappointed. Their products are always consistent and reliable, and their prices are very competitive. -

Ashley Williamswell-packaged and arrived in perfect condition. I would definitely recommend them to anyone in need of high-quality PCBs

Ashley Williamswell-packaged and arrived in perfect condition. I would definitely recommend them to anyone in need of high-quality PCBs

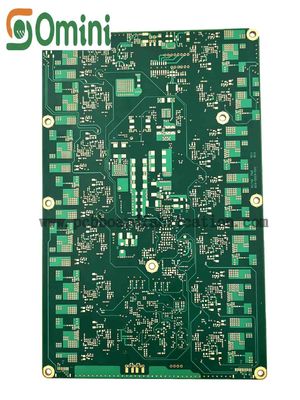

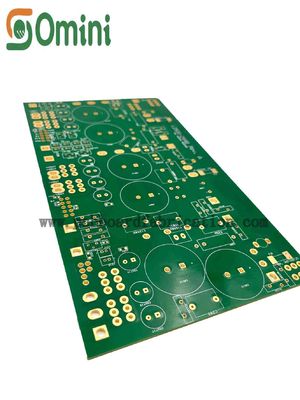

Welding Equipment Heavy Copper Printed Circuit Board 5 Oz Copper Thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Heavy Copper PCB | Base Material | FR4 |

|---|---|---|---|

| Copper Thick | 5OZ | Min. Line Spacing | 6mil |

| Board Thickness | 3.2mm | Min. Line Width | 6mil |

| Min. Hole Size | 16mil | Layer | 2 Layer |

| Application | Power Supplies, Welding Equipment, Power Distribution | ||

| High Light | Copper Printed Circuit Board 5 Oz,Printed Circuit Board 5 Oz Copper Thickness,Welding Equipment Copper Printed Circuit Board |

||

Welding Equipment Heavy Copper Printed Circuit Board With Thickness 5OZ

Quick details:

Base Material: Copper

Copper Thickness: 5oz

Board Thickness: 3.2 mm

Min. Hole Size: 16 mil

Min. Line Width: 6 mil

Min. Line Spacing: 6 mil

Surface Finishing: Gold Finger

Board Size: Customize Min:6mm*6mm Max:457mm*610mm

Application: Power Supplies, Welding Equipment, Power Distribution

Sheet thickness: 0.1mm-7mm

Maximum board width: Customize

Type: Heavy Copper PCB

Certificate: TS16949.ISO14001.ROHS. ISO9001

Color: Green, White, Blue, Black, Red, Yellow

Package: Vacuum packing

Description of Heavy Copper Printed Circuit Board Feature:

1. Carrying high current

When the line width is constant, increasing the copper thickness is equivalent to increasing the cross-sectional area of the circuit, so thickening the copper foil can enable the circuit board to carry a larger current.

2. Reduce thermal strain

The conductivity coefficient of copper foil is small (the conductivity coefficient is the resistivity; metal conductors are divided into the order of conductivity: silver→copper→gold→aluminum→tungsten→nickel→iron.). In the case of passing a large current, the temperature rise of the copper foil is small, so the thick copper plate can reduce the heat generation, thereby reducing thermal strain.

3. Good heat dissipation

Because copper foil has high thermal conductivity, the use of thick copper plates can play an important role in terms of heat dissipation.

Specification of Omini Heavy Copper PCB Printed Circuit Board:

| Layer | 2-24 layer |

| Material | FR4 |

| Board thickness | 0.4mm-5.0mm |

| Max.finished board side | 457mm*610mm |

| Min.drilled hole size | 0.25mm |

| Min.line width | 0.075mm(3mil) |

| Min.line spaceing | 0.075mm(3mil) |

| Surface finish/treatment | Electroless/immersion gold/ENIG/Immersion silver/Organic solderability |

| Copper thickness | 2 OZ - 8 OZ |

| Solder mask color | green/black/white/red/blue/yellow |

| Inner packing | Vacuum packing, Plastic bag |

| Outer packing | Standard carton packing |

| Hole tolerance | PTH:±0.076, NTPH:±0.05 |

| Certificate | UL, ISO9001, ISO14001, RoHS, CQC |

| Profiling Punching | Routing, V-CUT, Beveling |

| Assembly Service | Providing OEM service to all sorts of printed circuit board assembly |

![]()

![]()

![]()

![]()

![]()

FAQ:

Q1:Does Omini have enough capacity to prodece high-quality products?

A: Omini has 20 years of history in manufacturing PCB, more than 200 employees and 10,000㎡ factory area.We got the UL, ISO9001 certificates, and our production is sold abroad. We have engouh machines & equipment to ensure the quality, please check our Production Equipment list picturers.

Q2:How long does customers need to wait for the quotation and lead time?

A: We have a prefessional group to deal with your inquiry. In our working time, we will reply to your email within 30 minutes to show we have received your inquiry, Then we will send you our quotation in no more than 6 hours. Please noticed our working time is Monday to Friday, 8am to 24pm.

Q3:How can I make sure my PCB gerber is safety?

A: We promise we won't divulge your gerber to the 3rd party, one of our responsibilities is protecting customer information privacy and security, customer information can be included: company name, address, number, trademark, ect. And we could sign NDA with client if necessary.