-

Tyler MartinThe quality of the PCBs I received from this company was outstanding. They were well-made and exceeded my expectations.

Tyler MartinThe quality of the PCBs I received from this company was outstanding. They were well-made and exceeded my expectations. -

Olivia AndersonI've been using this company for all of our company PCB needs for years and I have never been disappointed. Their products are always consistent and reliable, and their prices are very competitive.

Olivia AndersonI've been using this company for all of our company PCB needs for years and I have never been disappointed. Their products are always consistent and reliable, and their prices are very competitive. -

Ashley Williamswell-packaged and arrived in perfect condition. I would definitely recommend them to anyone in need of high-quality PCBs

Ashley Williamswell-packaged and arrived in perfect condition. I would definitely recommend them to anyone in need of high-quality PCBs

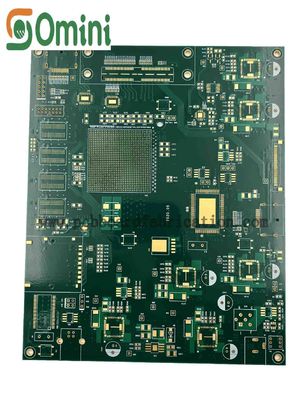

4L High Density Interconnect HDI PCB Golden Finger For Consumer Electronics

| Place of Origin | China |

|---|---|

| Brand Name | Omini |

| Certification | ISO9001, ISO16949, ROHS |

| Model Number | PCB-0021 |

| Minimum Order Quantity | 1PC |

| Price | Negotiate |

| Packaging Details | Vacuum packaging+foam cotton+carton+strap+ humidity card+Solder sample |

| Delivery Time | 3-8 working days |

| Payment Terms | T/T Paypal |

| Supply Ability | 30,000 square meter/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | HDI PCB | Base Material | FR-4 |

|---|---|---|---|

| Copper Thickness | 2 OZ | Min. Line Spacing | 3mil |

| Board Thickness | 1.6mm | Min. Line Wide | 3mil |

| Min. Hole Size | 4mil | Layers | 4 Layers |

| Application | Consumer Electronics, Vehicle Electronics, Digital Product, Laptop | ||

| High Light | HDI PCB Golden Finger,4L high density interconnect pcb,4L HDI PCB Golden Finger |

||

4L Golden Finger High Density HDI Printed Circuits Board for Consumer Electronics

Quick details:

Base Material: Rogers, Arlon, Nelco, Taconic

Copper Thickness: 2 OZ

Board Thickness: 1.6mm

Min. Hole Size: 0.1mm

Min. Line Width: 0.075mm

Min. Line Spacing: 0.075mm

Surface Finishing: Immersion silver/Gold Finger/Immersion tin/ENIG/ENEPIG

Board Size: Customize Min:6mm*6mm Max:457mm*610mm

Product name: 4L Golden Finger High Density HDI Printed Circuits Board for Consumer Electronics

Sheet thickness: 1.6mm

Maximum board width: Customize

Type: HDI PCB

Certificate: TS16949.ISO14001.ROHS. ISO9001

Color: Green, White, Blue, Black, Red, Yellow

Package: Vacuum packing

Description Of Golden Finger HDI Printed Circuit Board:

Insert one end of the circuit board into the connector card slot, use the pins of the connector as the outlet for external connection of the circuit board, make the pad or copper contact with the corresponding pins to achieve the purpose of conduction, and connect the circuit board Nickel gold is plated on this pad or copper skin, and it is called a gold finger because it is in the shape of a finger.

The standard hard gold plating method adopts electroplating method, which requires all fingers to be conductive during electroplating, so a wire will be added under the gold finger, firstly plate a layer of dielectric nickel on the copper surface, and then plate gold on the nickel layer according to the required thickness .

Before the fingers are gold-plated, cover all other non-gold-plated pads with tape, tear off the tape after gold-plating, and then cover the gold fingers with tape, and other pads are treated with tin spraying, OSP, and gold as required, and the pads are treated Peel off the tape on the gold finger after completion.

During molding, the gold fingers are bevelled to facilitate insertion into the card slot.

Specification of Omini HDI PCB Printed Circuit Board:

| Laser drilling aperture | 4-6mil |

| Dielectric layer thickness | 65μm / 100μm |

| Dielectric materials | RCC, LDPP |

| The inner line width | 3mil |

| Inner line spacing | 3mil |

| The outer line width | 3mil |

| Outer space, | 3mil |

| Unilateral inner pad diameter | ≥3mil |

| Unilateral outer pad diameter | ≥4mil |

| The minimum mechanical hole diameter | 0.15mm |

| Blind hole copper thickness | ≥20μm |

![]()

![]()

![]()

![]()

![]()

FAQ:

Q1:Does Omini have enough capacity to prodece high-quality products?

A: Omini has 20 years of history in manufacturing PCB, more than 200 employees and 10,000㎡ factory area.We got the UL, ISO9001 certificates, and our production is sold abroad. We have engouh machines & equipment to ensure the quality, please check our Production Equipment list picturers.

Q2:How long does customers need to wait for the quotation and lead time?

A: We have a prefessional group to deal with your inquiry. In our working time, we will reply to your email within 30 minutes to show we have received your inquiry, Then we will send you our quotation in no more than 6 hours. Please noticed our working time is Monday to Friday, 8am to 24pm.

Q3:How can I make sure my PCB gerber is safety?

A: We promise we won't divulge your gerber to the 3rd party, one of our responsibilities is protecting customer information privacy and security, customer information can be included: company name, address, number, trademark, ect. And we could sign NDA with client if necessary.